GIS supplies the software, printhead drive electronics and ink delivery systems that make industrial inkjet work in production. The kit is built for OEMs and integrators who want predictable output and fewer unknowns at affordable prices. Single pass and scanning are both supported. Variable data is routine. Job settings save and recall reliably. Maintenance is clear and fast. The outcome is stable print on real lines, shift after shift.

Applications range from packaging and décor to textiles, ceramics, coding and specialist deposition. Substrates vary. Duty cycles are high. We focus on control of data, heads and fluids so quality holds while jobs change, and volumes move up or down. Integrates cleanly with material handling, curing and finishing.

Packaging – Labels

Labels change often. Runs are short. Customisation is normal. Inkjet fits that reality.

GIS supplies software, datapath electronics and ink system components for the substrates used in label production. Paper, foils and films are supported. Variable data is routine. Serials, barcodes and security marks stay sharp. Setups load quickly so changeovers do not drag. Non-contact printing protects delicate stocks and avoids scuffing.

Where UV is used, control hooks allow true finishing on the line. The goal is clear output at speed with predictable colour and adhesion. Cost-effective runs and quick shifts from one job to the next.

Packaging – Carton Board

Cartons need print that fits converting. Creasing, cutting, and gluing set tight windows for registration. Digital opens up short to mid runs and versioning.

GIS technology works within cartonboard requirements and links software, drive electronics and ink systems so artwork changes do not stall throughput. Non-contact print keeps options open for coatings and embellishment. In-line variable data is available.

Speed and resolution scale with the brief. The outcome is practical: quality on common board types with a simpler path from design to finished pack.

Packaging – Corrugated

Boards are large and often uneven. Display work and retail-ready packaging still need clean graphics at useful speeds. Digital is changing corrugated for those reasons.

GIS brings drive electronics, software and ink system components to sheet and web formats so production stays flexible. Variable data can run in-line. Non-contact print avoids board crush.

Speed and resolution options cover POS, SRP and e-commerce packs. Short runs become economical and versioning does not force retooling. The aim is reliable output on real boards with fewer stops.

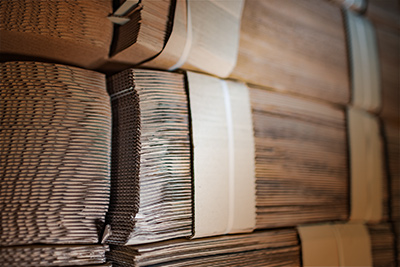

Materials Deposition

This is functional jetting. Printed electronics and semiconductor work need precise, stable placement. Fluids can include nanoparticle dispersions and other chemistries that demand control.

GIS supports that with accurate jetting, temperature management and recirculation. Quick prototyping is possible, then the same approach scales to higher volumes.

Parameters are captured and repeated, so results hold from trial to pilot. The focus is steady deposition, predictable thickness and clean edges at practical speeds.

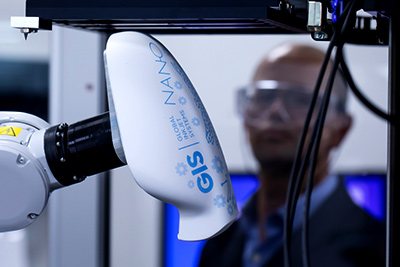

Complex Shapes

Direct to shape needs timing and gap control. Bottles, cans and other curved parts still require realistic graphics that land where they should.

GIS supplies enabling software, datapath electronics and ink system components for these builds. The system reduces breakages by using non-contact print. Smaller volumes and customised runs are supported without a tooling burden.

Results look like the final product, not a panel test. The benefit is efficient production with repeatable placement on cylindrical and complex surfaces.

Product Decoration

Brands need consistent decoration on plastics, glass and metals. Non-contact inkjet helps because parts vary and handling matters.

GIS provides the stack from printhead support and ink systems to responsive software. That supports cost-effective runs, smaller batches on demand and rapid changes for promotional work.

The platform keeps image quality stable while you switch designs or SKUs. The result is decoration that meets appearance and durability requirements at production pace.

Security Printing

Security work adds data control and traceability to normal production needs. Passports, plastic cards, tickets, and currency require variable data at speed and reliable registration for overt and covert features.

GIS brings software, drive electronics, and ink systems to these builds. In-line changes are supported. Resolution and speed are available for small text and fine detail.

Non-contact print keeps options open on substrates and workflows. The point is throughput with controls that satisfy process and audit.

Wide Format Printing

Wide format was an early inkjet market and still grows on print-on-demand logic. Jobs range from indoor POS to outdoor signage. Substrates include canvas, vinyl, paper, polyester and some textiles.

GIS supports this with printhead optimisation, ink system components, and enabling software. That allows quick introduction of new designs and consistent output across long panels.

Efficiency matters, so costs are kept in line with short or custom runs. The outcome is steady quality over size, with fewer restarts.

Décor

Décor relies on repeatable patterns and batch-to-batch consistency. Furniture laminates, flooring, and wallcoverings need flexible design changes without long downtime. Inkjet is well established here.

GIS already supplies software, drive electronics, and ink system components for these lines. The platform supports varied substrates and keeps image quality steady while designs switch.

Short runs remain economical, and scale is available when needed. The intent is simple: reliable décor output that fits production.

Textiles

Digital is a viable alternative to rotary and flatbed screen. Fashion, home, and technical textiles benefit from reduced volumes and custom patterns.

GIS enhances these systems with printhead optimisation, ink delivery and software. Dye and pigment workflows are understood. The platform supports efficient runs, small-lot customisation and fast introduction of new designs. It also copes with complex, non-repeat patterns.

Energy use can be reduced compared with legacy methods when configured correctly. The focus is stable colour and practical throughput.

Ceramic Tiles

Tile decoration is a mature inkjet application. Floor and wall tiles, cladding, and effects all need high coverage with durable results.

GIS supports these systems with drive electronics, ink management, and software. Non-contact print helps reduce breakages. Runs can be efficient at different volumes, with realistic designs that repeat reliably.

The aim is a quicker route to market with output that fits the demands of firing, handling, and installation.

Coding & Marking

Coding is variable data on primary and secondary packs. Dates, batches, 2D codes, and graphics must read first time at line speed.

GIS brings its established software, electronics, and ink systems to this sector. In-line changes are handled cleanly. Speed and resolution options support small fonts and barcodes.

Traceability features and non-contact print keep production flexible across substrates. Short runs remain cost-effective. The net result is clear codes with the controls that production teams expect.

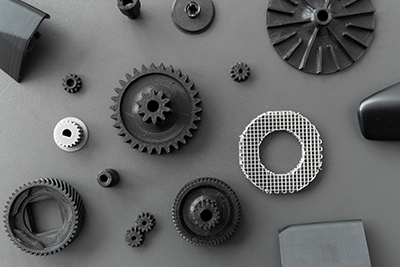

3D Printing

Additive manufacturing demands precision in jetting and material control. From prototyping to production, consistency and repeatability define success.

GIS technology supports 3D printing systems with advanced datapath electronics, software, and ink system components that manage complex fluids and multiple printheads in synchrony. Accurate placement and stable flow enable high-resolution builds, layer by layer. Parameters can be tuned and repeated, ensuring predictable deposition and strong interlayer adhesion. The result is reliable performance across materials and geometries — a platform that scales from research to industrial output with confidence.

Next step…

Connect with us

We’d love to hear from you.

If you are building a new machine or re-engineering a platform, talk to the GIS team. Want a more in-depth plan, or just a sanity check? Get in touch. We can set up a technical review through the form or take your call for a quick question.